Zehnder & Sommer AG

Quality for feeding your coils- and strips with highest speed and accuracyCoil line technology is one of our core competencies with many years of work within the stamping- and deep drawing industries. By Mantek Engineering you find full line technology and supply from the loader, de-coiler, straightener, feeder, press, process surveillance and safety to the re-coilers.

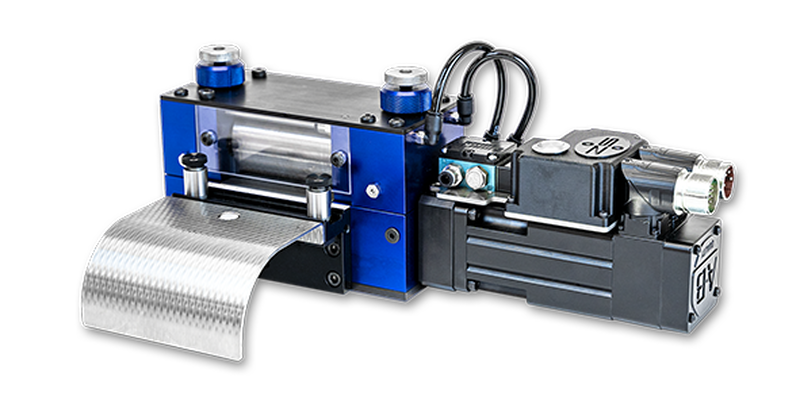

The coil- and strip feeders Mantek Engineering can offer our customers are proven technology, accuracy and quality from leading manufacturers in Europe. The coil- and strip feeders can manage various metal coils materials from the thinnest foil till 10 mm metal coils up to 1500 mm in width. We can manage the feed with gripper feeder or roller feeders from slow and long feed with a sequence of few strokes/minutes till high-speed presses with sequences op till e.g., 2.000 strokes/minutes.

Our high-tech suppliers support the fully automatic- and flexible stamping- and forming production in the coils foreseen by components in the medical, electronic, energy- and heavy-duty industries.

Zehnder&Sommer

Zehnder&Sommer - Quality for feeding your coils- and strips very fast and and accurate

Coil line technology is one of our core competencies with many years of work within the stamping- and deep drawing industries. By Mantek Engineering you find full line technology and supply from the loader, de-coiler, straightener, feeder, press, process surveillance and safety to the re-coilers.

The coil- and strip feeders Mantek Engineering can offer our customers are proven technology, accuracy and quality from leading manufacturers in Europe. The coil- and strip feeders can manage various metal coils materials from the thinnest foil till 10 mm metal coils up to 1500 mm in width. We can manage the feed with gripper feeder or roller feeders from slow and long feed with a sequence of few strokes/minutes till high-speed presses with sequences op till e.g., 2.000 strokes/minutes.

Our high-tech suppliers support the fully automatic- and flexible stamping- and forming production in the coils foreseen by components in the medical, electronic, energy- and heavy-duty industries.

The feeders are designed for specific material types, properties and thicknesses from a few hundredths of mm up to 10 mm depending on the purpose, process and press lines. The feeders can be supplied manually as automatic CNC adjusted for the specific work cell requirements.

The feeders can be provided with the necessary equipment for safe handling, safe opening/closure, precise edge alignment, loop control, manual or automatic material feeding, easy roll cleaning, roll changing etc.

Depending on work purpose and work range we offer the most efficient product range serie

- Electronic roller- or gripper feeders

- Programmable and optional manual adjustable feed length

- Band width: 10 mm – 1500 mm

- Thickness: 0,01 mm – 10 mm

- Feed length: 0 mm – >1000 mm/stroke

- Feed rate: 1 – 2000 stroke/min depending on feeding angle, feed length, pilot release, sling weight etc.

- Materials: Metal alloys as well as nonmetal foils

- High accuracy

- Very long proven lifetime

Advantages with a feeder from Mantek Engineering

The major advantages of our feeders are the operator friendly operation, flexibility, accuracy, quality, big technical range of work scope and very long technical lifetime. The equipment which will serve for many years with low operations cost and high energy effency.

Our feeders handle and feed the coils with optimal accuracy, safety and alignments for, e.g., stamping and/or deep drawing processes where we as well can provide the complete press line.

The feeders from Mantek Engineering ensure a stable and reliable coil workflow and highest accuracy and stroke co-ordinance in the press tool.